|

|

|

|

This is the car that started it all. Actually, it’s in fair condition by Midwest standards and for a high-mileage vehicle. We’ll watch it actually become a high-performance vehicle.

|

|

|

|

|

|

You can see there is just not much room in the engine bay for anything big, let along header clearance, with those primitive shock towers. We’re even looking at it with the engine gone, so image how close it is. The dashed lines indicate where the towers will be cut out to make room for the Heidt’s crossmember and upper control arms. Don’t worry about the big holes to fill. Heidt’s sells a panel kit to complete this part. Be careful not to get too hot around the frame rails. Carefully remove the lower control arm mounts. A plasma cutter works great here, but a saw or a cutting torch will get the job done also. |

|

|

|

|

|

This is a look at the rails after the trimming. The spindle centerline is marked, and the cutouts for the springs and rack and pinion are laid out. All these cutouts and lines are covered thoroughly in the instructions supplied with the kit from Heidt’s.

|

|

|

|

|

|

It’s tack welded in place. You can see how far the plates attach to the original rails, which will provide a lot of strength to them to handle the new suspension and engine torque.

|

|

|

|

|

|

The lower boxing place is clamped in place and tack welded. After you’re sure everything is in order, weld them together and to the frame rails.

|

|

|

|

|

|

The crossmember and spring towers are installed next. The crossmember is centered on the spindle centerline. The spring towers simply drop over the crossmember fully in place before installing the spring towers. Also notice that the rear spacer tubes for the Heidt’s full lower A-arms are already installed into the crossmember. It’s far easier to install them on the bench then in the car.

|

|

|

|

|

|

Install the coil spring very carefully. You can use a spring compressor, but the internal type will be in the way to install the shock, which is what holds the spring in place. Jack the lower are up enough to engage the upper ball joint and install the castle nut on it.

|

|

|

|

|

|

Install the shock. Again, the shock keeps the suspension together and limits the top out of the suspension. the shock has the bottom out snubber. The shock is a busy part on this type of suspension.

|

|

|

|

|

|

Install the rack and pinion. It simply bolts to the font of the crossmember. The mounting hardware is again supplied by Heidt’s with the crossmember kit. Tighten the hardware securely

|

|

|

|

|

|

Use a proper driver to install the seal. Do not hit it directly with a hammer. You could bend it and then have to get a new one. There is a reason the mobile tool truck has all those cool tools inside. |

|

|

|

|

|

Install the rotor into the spindle along with the outer bearing. Slip on the Tang washer and spindle nut. Snug the nut until you can feel the drag in the bearing, then install the outer cage and cotter pin |

|

|

|

|

|

Don’t forget to install the cotter pin. Just place the cage retainer over the nut and slip in the cotter pin. Bend the ends fully around the cage. |

|

|

|

|

|

Install the dust cap onto the rotor. Again, use the correct driver or a piece of tubing. If you try hitting the dust cap directly with a hammer, you’ll only smash it in and then it will look pretty dumb! |

|

|

|

|

|

Simply slip the column in place, hold it into the dash recess, and reattach with the original mounting bracket. There are shims that come with the column to fill the gap as the new housing is slightly smaller then the original, even though this column is specific to this car.

|

|

|

|

|

|

The column is then connected to the rack-and-pinion with this hook-up kit, again from Heidt’s. It includes shafting and two splined U-joints for the rack-and-pinion and column, and pins to attached it all together. |

|

|

|

|

|

The column hook-up kit is installed. The U-joints are slipped on the column and rack, and then measured for the shaft length. It is then cut and slipped in place. the U-joints are then cross-drilled and pinned with the supplied pins |

|

|

|

|

|

|

The notched and trimmed rails are now ready for the frame boxing plates also supplies with the Heidt’s kit. |

|

|

|

|

|

As you can see, everything is supplied with the crossmember kit, even the frame boxing plates.

|

|

|

|

|

|

The boxing plates are all pre-fitted to this frame, and will fit right up to it after the notching is done. the inner and top plate is one formed piece, and outers and lowers are separate plates.

|

|

|

|

|

|

The inner / top plate is clamped in place with the outer plate.

|

|

|

|

|

|

Now the fun begins. Start by installing the lower A-arms, per the instructions. You can see the spacers welded in and on the rear of the crossmember. These lower full A-arms give the suspension tremendous stability along with very smooth movement. You will no longer use strut rods with the modern type of suspension.

|

|

|

|

|

|

The upper control arms are next. These arms are also very stout and will supply good handling. The slots were the arms attached are used for the alignment, both caster and camber. This is the same as the original Ford design, and it’s easy to align. |

|

|

|

|

|

The spindle is next. You must use Heidt’s 2 inch dropped spindles to maintain stock ride height. Place it on the lower control arm and install the spacers and then the castle nut. Tighten up and install the cotter pin, unless you’re poing to blow it apart for paint.

|

|

|

|

|

|

Install the tie-rod ends onto the rack ends and then install them into the steering arms on the spindles. You can approximate the toe-in by centering the rack and pinion, aligning the spindles straight forward, and then adjusting the tie-rod ends so they insert into the spindles.

|

|

|

|

|

|

The brake - caliper brackets are next installed onto the spindles. The supplied Grade 8 hardware is used along with the correct spacers. These bolts must be tight! It is also highly recommended that some type of liquid thread locker be sued on these bolts.

|

|

|

|

|

|

Grease up the inner and outer bearings. There are bearing packers available for this job, but some of us are just old fashioned. Besides, this way it really looks as if your did a logt of work. |

|

|

|

|

|

Insert the inner bearing into the back side of the rotor and place the seal into its bore.

|

|

|

|

|

|

Install the calipers. They just slip over the rotors into the caliper brackets. Install the special caliper mounting bolts and tighten them securely. Make sure you put the calipers on the correct sides. The bleeders will always be on the top. The brake hoses can now be installed. They will be part of the brake lines that will be re-plumbed, as all the brake lines on the car this old are rusty and need to be replaced |

|

|

|

|

|

The inner fender openings are closed off with the kit from Heidt’s. The panels are precut and come with the hardware to complete the installation. |

|

|

|

|

|

The inner fender panels are bolted in place with the hardware supplied by Heidt’s. The lower holds must be drilled through the inner panels into the original fender wells to allow full attachment. This really makes the installation look finished off. |

|

|

|

|

|

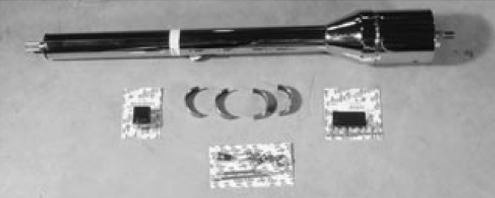

The new steering column to be installed is from Ididit in Tecumseh, Michigan. The original column on the 64-1/2 to 66 cars is one piece from the steering box to the steering wheel, and there is no way to remove it to hook it up to the rack and pinion. this beautiful column is a chrome plated tilt unit, but they are also available in polished billet aluminum or plain steel. This comes complete and is the only way to go

|

|

|

|

|

|

This is the final suspension installed. As you can see, the tubular arms and isc brakes will go a long way to improve this cars handling, performance, and appearance. This design is light years ahead of the original suspension design, and the performance difference when it’s driven will be unbelievable. |

|

|

|

|

What’s It Cost?

Prices start ad $1785

Level of Difficulty

Intermediate

Tools

Welder - Cutting Tools - Hand Tools

Time:

Can be completed in one day with assistance.

|

|

|

|

SOURCES

Heidt’s Hot Rod Shop Inc

Dept MF

111 Kerry Ln

Wauconda, IL 60084

800-841-8188

Ididit Inc

Dept MF

610 S. Maumee St

Tecumseh, MI 49286

517-424-0577

|

|