|

|

|

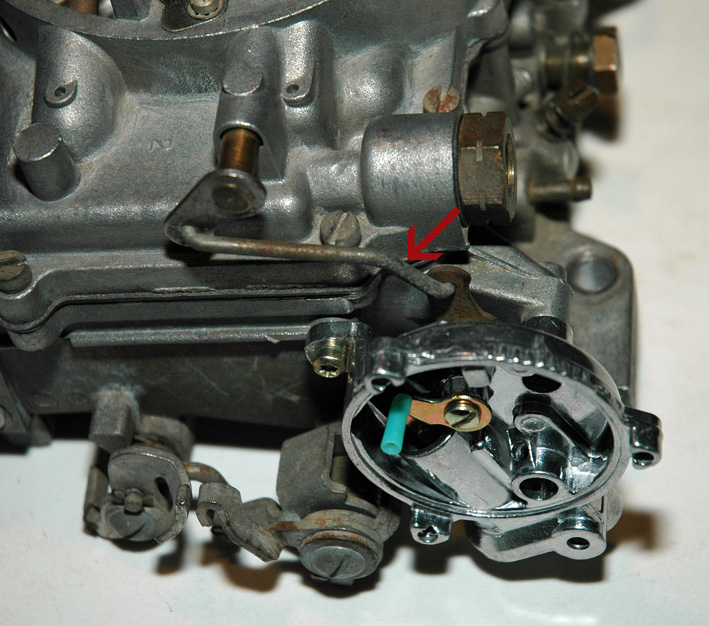

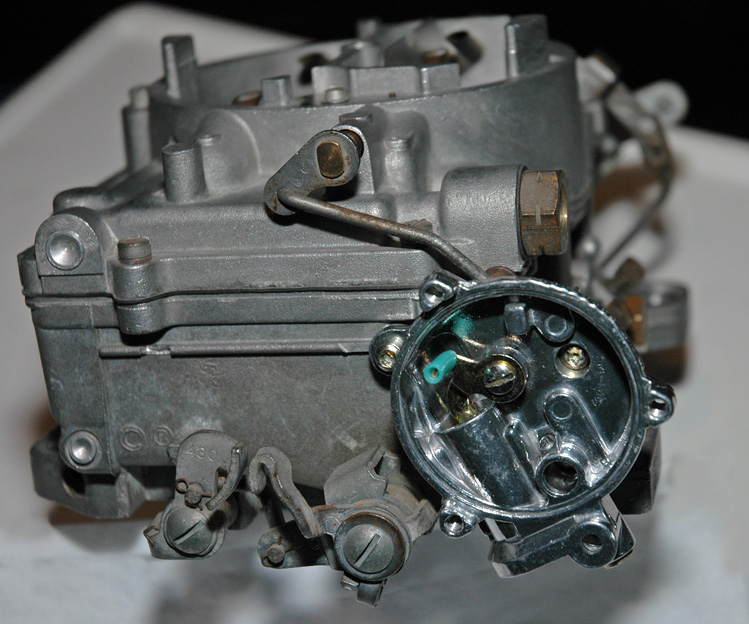

This early Carter AFB 4-barrel carburetor is equipped with an automatic choke that is actuated by heat transmitted from the exhaust manifold via the tube entering the choke housing. No exhaust gas is used in the process, just heat radiated via the tubing. A piston activated by vacuum, located inside the choke housing, assists in holding the choke butterfly open when the engine has reached operating temperature. |

|||||||||||||||||

|

|||||||||||||||||

|

Shown are all of the items included in the Edelbrock electric choke kit (#1478) for converting their manual choke equipped Performer series carburetors to electric choke. It was not created for use on the AFB but parts from the kit make the conversion possible. |

|||||||||||||||||

|

|||||||||||||||||

|

These items from the kit are not used when converting an AFB carburetor from an exhaust / engine-heat activated choke to an electrically actuated choke. |

|||||||||||||||||

|

|||||||||||||||||

|

The pivot shaft and linkage from the AFB (above) are used instead of the ones (below) supplied in the Edelbrock kit. |

|||||||||||||||||

|

|||||||||||||||||

|

This view of the back side of the new Edelbrock choke housing with the old AFB pivot shaft arm and linkage installed shows that the arm points up and opens the choke butterfly as it swings to the rear. O-ring (arrow) fits in the recess in the choke housing and seals the vacuum supply passage on the carburetor base. |

|||||||||||||||||

|

|||||||||||||||||

|

This view of the back side of the new Edelbrock choke housing with the linkage supplied in the kit installed shows that the arm points down and opens the choke butterfly as it swings to the front. This is the way that the choke linkage travels in Edelbrock Performer carburetors. |

|||||||||||||||||

|

|||||||||||||||||

|

Vacuum is supplied to the piston in the choke housing through this passage (arrow) that is plugged with a lead seal on carburetors without a choke like these AFB carburetors originally intended for racing. |

|||||||||||||||||

|

|||||||||||||||||

|

Lead seal (arrow) can be removed from the passageway by inserting a knife blade under the edge and lifting the plug up. Brass insert in passage is stock item in stock carburetors. |

|||||||||||||||||

|

|||||||||||||||||

|

Piston in the choke housing is at the bottom of its travel and the linkage (arrow) at the rearmost point of its travel when the choke butterfly is open. |

|||||||||||||||||

|

|||||||||||||||||

|

Vacuum from beneath the venturi in the carburetor has drawn the piston down in the choke housing keeping the choke butterfly open once the engine has reached operating temperature. |

|||||||||||||||||

|

|||||||||||||||||

|

Electric choke uses the same type of coiled spring cover as the one in the older style engine-heat activated choke that relaxes the spring, uncoiling as it is heated. However, instead of using heat from the exhaust manifold or intake, the electric choke uncoils the spring via an electric heating element in the cover. Baffle plate and gasket serve to seal and separate the choke housing from the cover. |

|||||||||||||||||

|

|||||||||||||||||

|

Edelbrock choke housing mounts to the carburetor in the same manner as the old choke housing via three screws supplied in the kit. Piston linkage from the kit bolts to the pivot shaft from the AFB indexed by the flats on the end of the shaft. |

|||||||||||||||||

|

|||||||||||||||||

|

Baffle separates the spring housing from the piston area. The actuating arm on the piston linkage projects through the slot in the baffle. The baffle is located in the housing by the button-shaped recess in the bottom of the baffle. |

|||||||||||||||||

|

|||||||||||||||||

|

The gasket and spring housing are held in place with three screws and butterfly clips around the raised ridge on the cover. Black ground wire supplied in the kit plugs onto the negative tab on the housing and is grounded at the cover attachment screw |

|||||||||||||||||

|

|||||||||||||||||

|

The red wire supplied in the kit plugs onto the positive terminal of the choke cover and connects to a 12-volt terminal on the ignition side of the ignition switch supplying continuous power while the engine is running |

|||||||||||||||||

|

|||||||||||||||||

|

Choke butterfly is located on a shaft at the top of the carburetor inlet. It pivots off center which assists in holding it open as air flows through the inlet into the engine |

|||||||||||||||||

|

|||||||||||||||||

|

Wiring on the finished conversion will be dressed and included in the engine harness running alongside the rocker cover on its way forward to the alternator. |

|||||||||||||||||

|

|

|

||||||||||||

|

IMPORTANT NOTICE: All content in the articles in this section are the property of the author of the article and all advice and instructions are intended to be just basic guidelines for the undertaking of any project, and not intended for use by individuals who are not experienced in the particular field. We advise that you contact the manufacturer of any product or tool you are using for complete instructions. We also advise you to always use the appropriate safety equipment for the tools and products you are using. Hotrodhotline.com and its contributors disclaim any responsibility for the consequences of using the articles or procedures described in any of the articles in this section and by using this site you agree to these terms. No portion of any of these articles may be used without the written permission of HotRodHotLine.com and the Author. |

|||||||||||||

|

Copyright 2007-2011 Hotrodhotline.com All Rights Reserved |

|||||||||||||