Building a 1955 Chevy "C" Gasser

By noderel:

|

Building a 1955 Chevy "C" Gasser By Dave Brackett |

|

|

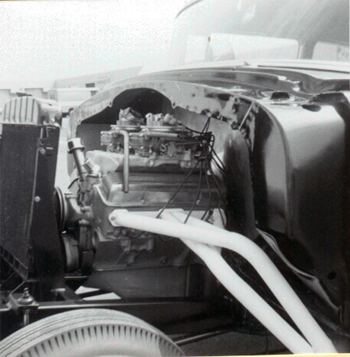

In 1966, I had opened my first business in Anaheim, Ca., called "Brackett Speed Products". I built headers, dragsters, and all kinds of hot rods. A customer came in with a 55' Chevy "C" gasser and wanted me to lighten the car and build headers for the small block Chevy motor. I started by removing all the front sheet metal and bolting together a one piece front end, with no inner fender wells. |

|

|

| Now to get rid of all the weight, I cut off the frame at the firewall. I got some 2" by 4" rectangular steel tubing and built two new frame rails, tapering the front down to accept a tubular front cross member. I added a light leaf spring on each side, mounted shocks and built a straight tubular axle, then installed a light Crosley steering box and made a drag link to complete the steering. | ||

|

You need to remember that tires did not have much traction back then, so the front of vehicles was raised to try to get more weight transfer on the rear wheels. This is why you see straight tube axles and the necessity to reduce weight in the front. The motor and radiator were remounted farther back. Now to address the firewall. I cut away the existing firewall, and built a new one farther back to accomodate the new 10% engine setback. |

|

| After making an aluminium tunnel, I attached the new floorboards, firewall and tunnel and blocked off all openings. After installing hood pins, I installed the one piece front end, it was a lift off style. | ||

|

I remounted pedals and seats in a more rearward position, to fit the new motor location. A roll bar was added and the package was complete, except for headers. I made headers that ran out through the fender well, there was no inner fender skirts, and down behind the front tires. As you can see in the photos, the car was now very light, there is no motor in, but I am picking the car front up. I built four of these cars in about a year. One was done more quickly and cheaply because I only added a new front cross member to the original frame and mounted a straight tube axle with front transversal spring and wishbones. In this one, the motor stayed in the original position, no firewall work was done. This was a street car, the other three were drag race cars. On one of the cars, I did something sneaky. Gassers could only move the motor back 10% of the wheelbase. |

|

|

|

These cars were all two door styles. One customer wanted more of an edge, so I removed the long two doors and got two four door front doors at the junk yard. These doors were about 7 inches shorter than the two door doors. I installed the shorter doors and cut the body and frame the same amount. The end result was the motor was 7 inches closer to the rear end and there was also a weight savings. This car ran very well and no one ever questioned the wheelbase. At a time when stock cars were becoming race cars, the key to drag racing success was saving weight. This was long before fibreglass and aluminium body parts were available, so weight was saved by removing upholstery, unneeded items, and altering the heavy frames of the day. It would be a while before tubular chassis were available for 55' Chevy's. I wonder where all these cars are today, maybe still racing? |

||

|

|

|

|

|

|